Welcome to Angled Discourse. This blog will touch on all things spray wall and we’ll get into the nitty gritty, theory side of things in due time. First, however, some housekeeping to get us all on the same page:

In this guide, we’ll go over best practices for attaching your holds to your board, aka hardware.

-

What type of bolt or screw you should (and shouldn’t) use

-

Why it matters

Maybe not thrilling, but important. Let’s get this one in the books.

First Things First

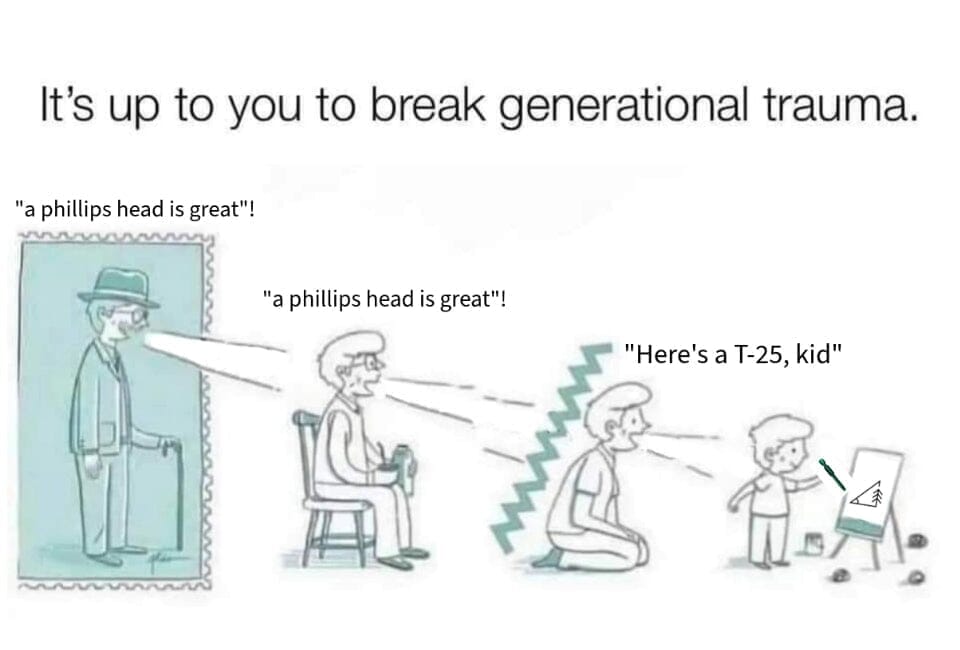

If there’s a singular, most important takeaway here, it’s this: get rid of any phillips head you have. Right now, in the trash. You don’t need the sort of negativity in your life that the phillips head emits, and more importantly - you shouldn’t be spreading it. There was a time and a place for Phil, and that’s in the past. It’s 2025 and the “25” stands for T-25, get familiar.

Why does it matter?

-

Owning a Board Requires Maintenance: Make things easier on yourself. Use standardized screws and bolts with the same heads. Your bolts should be 3/8-16 thread size with a 5/16” or 7/32” Hex head. Screws should be T-25’s, of course.

-

Think Ahead: Most likely, your board will need to come down one day. If you’ve never had to demo something that someone else built using various types of hardware and bit types - it’s something that I wouldn’t wish on my worst enemy. Just be consistent.

-

Safety: Have you ever pulled alllll the way to that jug, feet cutting, body careening through space, and right when you latch and start to weight it - a spinner!?! Now you (or your buddy) are on the ground, surprised, and hopefully, on foam. Let’s just avoid this!

The Right Tool for the Job

Impact drivers are great, I use them all the time. They also make it super easy to drive screws in way farther than necessary. This could crack or even break part of a hold right off, especially wood. Get them good and snug, but you never want to drive screws deep into a surface.

Below is a short list of what you need in your kit:

-

Impact driver or drill

-

Bits: 5/16” and 7/32” hex, and T-25

-

Hand wrenches

-

5/16” and 7/32” hex

-

⅜-16 tap, for cleaning and fixing t-nuts

-

7/32” drill bit and a countersink bit

Let’s Spray

Pick a hold. Is it a bolt-on? Great. Does it have a spot for a set screw, or does it need one? If it needs one, grab your drill bit and countersink bit. Be careful not to angle the screw hole too much, you want to stay around perpendicular. Now, you need a bolt that’s about an inch longer than the bolt hole.

When attaching a bolt-on, if you find yourself stripping the t-nuts too often, try starting the bolt with your hand wrench and then switching to the impact. You’re also going to want to give it a crank with the hand wrench after.

Take a look at the front of the hold, does the bolt head stick out? If so, consider a button head or flathead bolt instead.

Next, a short set screw will finish the job. This does not need to be driven far into the hold.

Screw-ons:

Always use #9 construction-rated screws. A few more options here, but it’s fairly simple. Just be sure to have the right length screws and bear in mind that a single hold could use different length screws. You want to have about 1½” of thread stick out behind the hold. Too long or too short and the screw won’t hold correctly.

Use Your Noggin’

I believe in you! I also believe this blog will be much more interesting to you in the future, but we have to start somewhere! Thanks for reading.

-Lincoln